There’s the rub: the painful history of the blister

In October 1983, Lars Backsell was sitting on a train from Stockholm to Gothenburg. The 28-year-old, who worked for medical-device firm Coloplast, was a runner and he frequently developed blisters. ‘I had tried almost everything with Band-Aids,’ he recalls. ‘But even with the most careful preparation, that simply wasn’t good enough.’ Coloplast had recently diversified from abdominal surgery and incontinence products to a dressing for wound care. Comfeel was a ‘hydrocolloid’, a newly developed substance that could absorb liquid without losing flexibility or adhesiveness. Backsell had already experimented with putting Comfeel on his heels when he ran and found it reduced blistering. Now, on the train, he found himself sitting next to a nurse who worked for the Swedish army. The two discussed the problems the military experienced with blisters. ‘I took the chance to sell the concept of trying my idea on soldiers,’ Backsell remembers, and they agreed to run a test. Two weeks later, on a wet day in the Gothenburg suburbs, Backsell and the nurse put Comfeel, framed with Hansaplast [Elastoplast] tape, on the heels of 25 soldiers. A control group had ordinary Band-Aid plasters. A third group wore no protection at all. Backsell set up an aid station in a forest, part of the way along the march route. ‘I had never seen so many ugly feet – and never felt such a smell,’ he recalls. Soldiers not protected in advance were treated with Comfeel for the remainder of the march. According to Backsell, the result was overwhelming. Everyone that tried Comfeel (both preventive or after developing blisters) could continue without problems. Backsell put the used ‘bandages’ in a shoebox. A couple of days later, he phoned Folmer Halskov, the president of Coloplast in Denmark to explain that he had a product idea. The boss sounded hesitant. A week later, Backsell entered the president’s office with the shoebox of used bandages. ‘I was pretty nervous,’ he remembers. Not only did the contents of the box stink, but Danes and Swedes have a long-standing antipathy…

This story will tell you everything you ever wished to know about the runner’s eternal nemesis – the blister – and possibly a little more, too. We’ll see how attempts to avoid them have varied across time and place. We will explore the physiology of their formation and reveal the state of the art for prevention. And we’ll show how the latter, in popular imagination and clinical reality, has failed to correspond to the former. As Rebecca Rushton, a podiatrist who specialises in blisters, explains, ‘Blister management is in a terrible state. Everyone’s doing different things.’

Today, numerous products claim to prevent or treat blisters. And there are many to treat – one pharmaceutical company found that in their top five European markets, approximately one in four people suffer from a blister each year. Meanwhile, as many of us know from painful experience, blister incidence during marathons is as high as 39 per cent.

Folklore surrounds best practice to prevent blisters. But the wide variety of approaches also shows that none of them are truly effective. ‘When there’s a bunch of different treatments out there, it means nothing probably really works,’ explains Dr Martin Hoffman, a retired University of California professor who has published research on blisters. However, we may be in a better position today to handle blisters than ever before.

Lessons from blistery

Our quest to avoid blistering is a long one. In September 1991, two German tourists stumbled across a frozen body on a mountain on the Austrian-Italian border. Investigations revealed the corpse, christened Ötzi, lived between 3,400 and 3,100BC. Researchers probed Ötzi’s diet, cause of death and clothing. Eventually Czech academic Peter Hlaváček turned to his feet.

Hlaváček, who had once retrospectively diagnosed a 17th-century Austrian general with syphilis from the uneven wear patterns on his boots, faithfully reconstructed Ötzi’s shoes. The leather on the sole came from a bear; deer hide formed the upper. Straw served as insulation, moss as lining.

When Hlaváček persuaded Czech Alpinist Vaclav Patek to test his replica Ötzi–shoes in the Alps, he found the peak pressure points of Ötzi’s footwear half as high as in modern hiking boots and 75 per cent lower than in trainers. ‘It is a miracle,’ said Hlaváček in 2005. ‘In these shoes you can practically not obtain the blisters.’ Unfortunately, the need to regularly replace the moss lining limited commercial opportunities for Ötzi–shoes.

Three millennia after Ötzi’s death, a Roman soldier on Hadrian’s Wall received a package. ‘I have sent you... pairs of socks from Sattua, two pairs of sandals and two pairs of underpants,’ reads a message on a tablet found at Vindolanda fort, just south of the wall. Roman soldiers originally wore a leather sandal called a caligae, with straps designed to avoid rubbing certain parts of the feet. As the sock delivery showed, though, sandals alone were not ideal for chilly climates.

Later Romans wore an enclosed boot, termed by archaeologists the ‘Ramshaw style’. As with Ötzi’s footwear, ancient technology was not necessarily inferior to modern. In 2004, 12 students attempted to march across the Alps dressed in Roman apparel. Five of the 12 switched to modern footwear, but the others persisted with Ramshaws. ‘Surprisingly, the Ramshaws caused less blisters than the modern boots,’ Florian Himmler, the academic who organised the trial, wrote in the Journal of Roman Equipment Military Studies in 2008. (Though he acknowledged that the nails driven into the soles for grip were not ideal on roads.)

By the First World War, the management of blisters was still a key part of military life. Officer-poet Siegfried Sassoon recorded the ritual in verse.

Those stupid, trustful eyes stare up at me

Yet, while I stoop to Morgan’s

blistered toes

And ask about his boots, he never knows

How glad I’d be to die, if dying could set him free

From battles.

During the Second World War, the management of soldiers’ feet became the target of intense research. You can still buy, on darker corners of the internet, unused, foil-wrapped cakes labelled Hirschtalg, which were issued to German troops. Literally translated as ‘deer tallow,’ Hirshtalg is a preparation, indeed first made from animal fat, used to treat feet in Germany since the middle ages. (Today it comes in tubes, courtesy of Scholl). The global nadir of blister work though came at Sachsenhausen concentration camp, north of Berlin.

Sachsenhausen came to hold over 200,000 people, from political prisoners to Jews and Jehovah’s Witnesses. The camp had a ‘Shoe-walking unit’ with a 700m track made of concrete, cinder path, loose sand, mud, chippings, coarsely gravelled path and cobbles, As German author Norman Ohler explained, ‘This was designed to provide a cross-section of all the roads in Europe that German soldiers walked on during their campaigns.’

The unit assessed alternative materials to construct boots and under the oversight of master cobbler Dr Ernst Brennscheidt, inmates were forced to walk the track in deliberately ill-fitting trial footwear. Marian Szlachciński spent two years in the shoe unit. As an 87-year-old, in 2014, he recalled walking up to 48 kilometres each day with blistered feet.

Up to 20 people died on the track each day. After the war, Brennscheidt served a few years forced labour in Russia; on his return, he opened a shoe shop in West Germany.

Science friction

Blister research never again plumbed such depths but military research continued. Conducted without the approvals required today, some experiments retained a hair-raising quality.

The first robust investigation of blister formation in a controlled environment came in the 1950s. At the British Army’s Experimental Research station at Byfleet in Surrey, Dr Paul Naylor employed mechanised heads made of polythene and silver to rub study subjects skin to create blisters.

Naylor found variation in how long the same rubbing motion took to raise a blister in candidates (ie some people are more blister-prone than others). He also identified the role played by friction, the resistance that one surface encounters moving over another, rather than just pressure, the perpendicular force applied to a surface.

‘There is an inverse relationship between the frictional force and the number of rubs required to produce a blister,’ he wrote. ‘Factors which increase friction, such as moisture, reduce the number of rubs which the skin can withstand. Factors which decrease friction, such as grease or powdered talc, increase the number of rubs which the skin could withstand.’

Naylor’s work was continued on the other side of the Atlantic by Marion B. Sulzberger. Born in New York, Sulzberger served as a naval pilot from 1917 to 1918, studied dermatology in Switzerland and spent the Second World War studying the impact of chemical weapons on human skin. Post-war, Sulzberger turned his energies to blisters. From 1964 to 1970, in the words his fellow dermatologist and collaborator William Akers (himself the inventor of the SPF scale for sun cream), Sulzberger “mounted a scientific assault against this plebian disease.”

Sulzberger also blistered human subjects with rubbing machines – refining Naylor’s apparatus so he could determine when blisters began to form while rubbing was still in process. His research found that dry and ‘flooded’ skin produced less friction than moist skin. He determined that, despite vigorous rubbing, the temperature in the skin never rose more than 3.5C, so friction blisters are not a burn. He also determined that blister formation took place within the skin, not on the surface. ‘It is the differential movement of the upper layers to-and-fro over the lower ones which produces the shearing effect between the more superficial and the deeper epidermal structures,’ he wrote in 1972.

Sulzberger’s breakthroughs had a rather more colourful context than simply making the world a better place for endurance runners. He saw his work on blisters as part of a wider theory he termed ‘Idiophylaxis’, which held that, via vaccines and other biotechnology, the US could create super-soldiers to prevail against communism. Still, despite the element of mad Cold War pseudo-science, Naylor and Sulzberger laid the foundation for a scientific understanding of blister formation that still largely holds.

Research in the last 40 years led to more nuance. A study on US Army officer cadets in 1999 found that black skin was less likely to blister than that of Caucasian, Asians or Hispanics. Other rubbing experiments found skin temperatures as high as 50 °C, but that did not change Sulzberger’s finding that blisters do not resemble second-degree burns. Another US army study found that preparatory use of an antiperspirant solution on feet for five nights before a 21km march more than halved blister occurrence. However, the chemical used, aluminium chloride hexahydrate, also caused significant problems with skin irritation.

Despite these advances, the heart of the matter remains as Naylor and Sulzberger showed decades ago: blisters aren’t just caused by pressure; a second critical factor is repeated friction forces, causing internal shear within the skin. A sheer force is produced where there is a lateral friction force across a surface.

‘Pressure does contribute directly to damaging stresses, but it is wrong to think of it in the absence of friction-induced shear,’ explains Marty Carlson, who designs orthopaedic and rehabilitation equipment. To envisage this, place a finger on the back of your hand, apply a pressure and move it from side to side. The finger stays on the same piece of skin. There is no movement between skin and finger. Yet the skin itself stretches. That is shear.

These forces, repeated many times, create a ‘fatigue effect’. At points in the running- gait cycle, shear forces peak on certain vulnerable, usually bony, areas of the foot. After a certain duration of activity, the damage caused by each individual shear cycle increases. And blisters appear.

To understand more about the how, why and where of the blistering process, you need to know that the epidermis – aka your skin – has four layers. From the surface down these are the corneum, granulosum, spinosum and, finally, the basale, where skin cells generate.

Shear forces cause clefts at the junction of the granulosum and the spinosum, which is why surface calluses on the surface don’t protect you. ‘People think that if we build up calluses, we’re not going to get blisters,’ says Rebecca Rushton. ‘That assumes it’s a superficial-to-deep wear injury. But it’s not. It’s a shearing of the internal skin layers that is the actual cause of the blister damage. So calluses have no impact.’

Friction blisters are largely unique to plantar or palmar skin, found on the base of the foot or the palms of the hands. The reason blisters form on plantar skin, but not elsewhere, is that plantar’s upper two layers are tougher. On the forearm or torso, all layers of the epidermis fracture at roughly the same rate so an abrasion will eventually scab over. On palms or feet, the outer layers stay intact while the underlying cleft forms. That fills with clear interstitial fluid; there are no blood vessels in the epidermis. Hence the fluid-filled form of the blister. Blood blisters require deeper and longer trauma.

This prime role of shear and friction in blister formation is accepted in scientific literature. However, the broader medical establishment and athletes, amateur and professional, are yet to catch up.

In his boss’s office in Copenhagen in 1983, Lars Backsell opened the shoe box containing the bandages. A stench emerged. ‘Either he likes it, or I will get fired for having moved totally outside my job description,’ he remembers. After Backsell spoke for half an hour, the boss said he would consider the idea. Three days later he phoned Backsell and asked him to form a team to see what Coloplast could do in the ‘sports consumer business’. They hand-sewed the first plasters, adding polymer backing to the hydrocolloid. When it came to naming the new product, Backsell’s team wavered between two options: Achilles or Compeed. They settled on the latter.

In 1984, Backsell took an early iteration to the Swedish ski resort Åre. He handed Compeed to sports shops for free to see if they sold. As he left one establishment, Backsell overheard the salesman remark, ‘That guy wanted me to believe that this was something people would like to buy to prevent a simple blister, for a price five times that of Band-Aid – such an idiot.’ The test price was 10 Swedish krona, which today would be about 25 krona, or £2.20.

But pay they did. An article in Apoteket, the journal of the Swedish pharmacy industry, was the breakout. In 1984-85 Compeed sales for Coloplast were around 40-50 million Danish krona. That is roughly 88-109 million krona in today’s values, equivalent to around £10.6-13 million. Given they were not selling direct to individuals, the consumer market was considerably larger, around 150-200 million Danish krona. That is around 328-438 million krona today, or £39-53 million. Johnson & Johnson acquired Compeed from Coloplast in 2002, and held it for fifteen years, before selling it to Paris-based firm HRA Pharma in a 2017 deal estimated to be worth more than 100 million euros.

Today Compeed is the world’s leading anti-blister brand. Much of its marketing still concentrates on sport, but the manufacturers have also found that women buy them for ill-fitting formal shoes. ‘This has prompted a lot of work making the bandages as discreet as possible,’ explains Tune Bjarke Bonné, a physicist who works for Coloplast.

Compeed, with its carefully designed backing and aesthetic clamshell cases, is as elegant as it is dominant. However, in the world’s most intense laboratory for blister treatment, it is disregarded.

Peak force

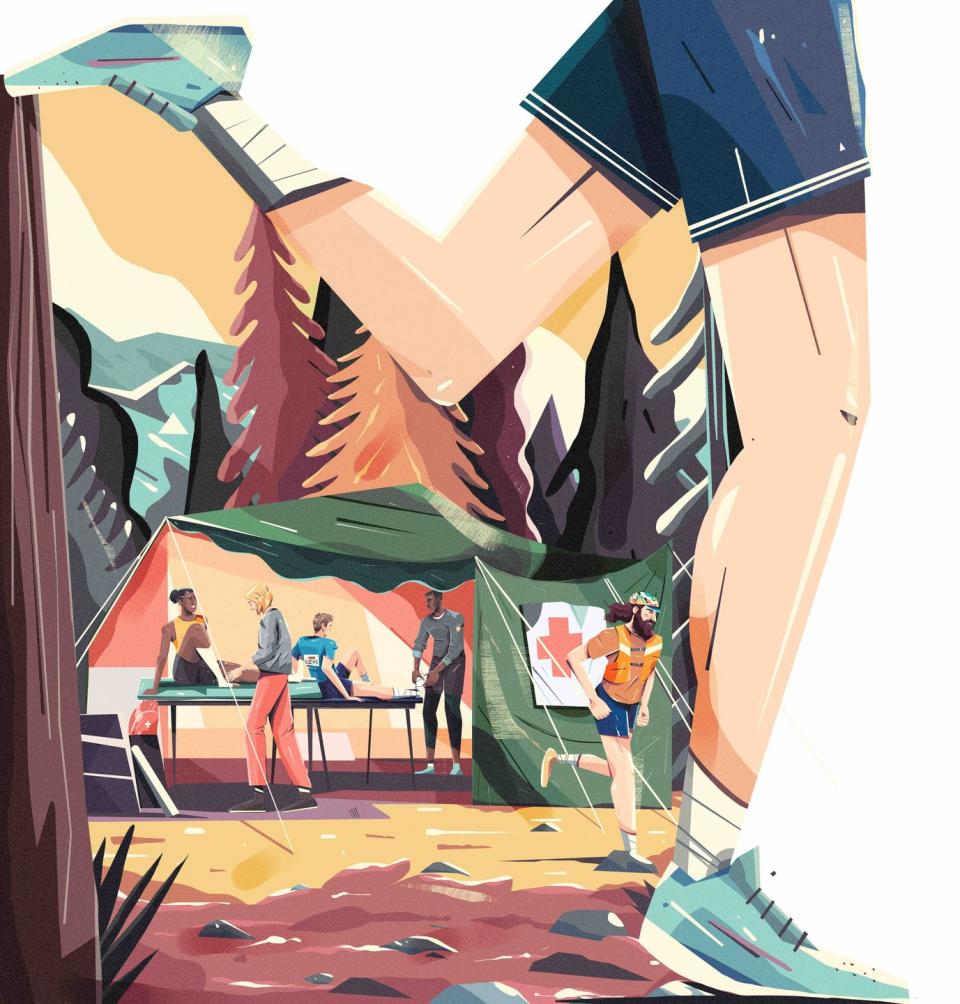

The Mile 55 aid station in the Western States Endurance run – the original 100-mile ultra – is a collection of tents at Michigan Bluff high in California’s Sierra Nevada Mountains. Over the past decade, two individuals have provided footcare at Mile 55. One is John Vonhof, an American runner, former paramedic and emergency room and orthopaedic technician whose opus Fixing Your Feet is now in its 6th edition. His partner is Tonya Olson, a Florida-based physiotherapist, ultrarunner and footcare specialist.

The race starts at 5am and the leaders reach Mile 55 by early afternoon. These are elite pros and their well-acclimatised feet experience few problems. ‘They’re not out there as long,’ says Olsen.

The carnage comes later. Blisters are common on toes, heels and the sides of feet. In the most extreme circumstances, Vonhof and Olsen see complete ‘delamination’ of the sole, with the top layer of the epidermis coming fully away from tissue below it. ‘They’ll say it feels like the bottom of my foot is one big blister, or the ball of my foot is on fire,’ Olsen explains. ‘You can touch the skin on the bottom of the foot and wiggle it.’

Olsen and Vonhof’s weapon of choice is tape: ideally a woven product such as K-Tape. In cases of full delamination, they mummify the foot from toe to heel. That generally enables an athlete to carry on running. When it comes to toes, Vonhof and Olsen use a careful butterfly technique to avoid seams. They avoid Compeed. ‘It is horrific for endurance events because it attracts water [and] balls up,’ says Olsen. ‘Compeed is made to be placed on top of a blister and to stay there until that blister, the skin underneath the blister, has healed enough to be exposed to the air and not be painful. It is not created to withstand the stresses and frictions of being inside in a shoe in an endurance event.’

When they encounter athletes who have applied Compeed themselves it tends to have become a gelatinous ball that’s almost impossible to remove. ‘I have to cut around that, and now we have a higher friction point over the damaged skin and we have to just do damage control,’ says Olsen. Olsen will only apply Compeed at the end of a race; then it has a chance of staying on long enough to permit healing.

Both Tune Bjarke Bonné, the current Compeed developer, and Lars Backsell, its creator, push back at the notion that attempts to remove Compeed can rip off skin. ‘I have not heard about that,’ the former says, adding that ‘It’s all a question of how much force you’re putting on, of course.’ Backsell acknowledges the saturation issue – pointing out that Compeed can absorb 11 times its own weight in water. It can ‘get sort of attached to the sock,’ he says. Yet, Backsell suggests, if you ‘frame it with Band-Aid’ it becomes more resilient for long events.

Elsewhere in ultrarunning, the rejection of Compeed seems universal, but treatment varies greatly. Marathon des Sables runners are advised to buy oversized shoes to accommodate dressings and swollen feet, and use gaiters to keep sand out. They are also counselled to prepare feet in advance. Starting six months before the race, recommended options include either a mixture of 60% alcohol, camphor and phormol, lemon juice or a commercially available hardening solution like Tano. For the last month an ‘anti-chafing’ cream like NOK or Pedirelax is recommended.

Each evening of the six-day event a mini-clinic springs up. Runners wait for the medics with their feet in baths of disinfectant. ‘The first two days are OK – just small blisters on toes or under the sole,’ says Alice Gavet, a French doctor who has served on the medical team at the MdS. ‘The real problems start on the third and fourth days.’ In the case of severe blistering, the medics take a syringe loaded with eosine, pierce the blister, drain the fluid, and reinject the antiseptic. ‘That dries it and disinfects it,’ says Gavet.

The real danger is infection – notably from streptoccus pyogenes. Gavet rarely sees such infection in France, but it’s widespread in the Sahara. The doctors respond aggressively with antibiotics. They cover blisters with dry gauze compresses held in place with tape. ‘We don’t use Compeed because they’re very difficult to take off,’ says Gavet. Runners sleep with dressings applied, ready for an early start.

At Racing the Planet endurance races, each runner is asked to carry their own safety pin. Whether to pierce blisters at all is a vexed subject. Conventional medical wisdom warns against, pointing out that an intact blister ‘roof’ prevents ingress for infection. However, in reality, if a blister is full, and you have to keep using your feet, drainage is required. (A 1968 study found that if blisters were drained three times within the first 24 hours, or once at 24 and 36 hours, blister roofs were most likely to remain intact. By contrast removing the blister roof before 48 hours resulted in the greatest discomfort, inflammation, and in one case, secondary infection). In RTP events, medics swab blisters with alcohol, then use the runner’s pin to pierce the ‘distal end’.

‘The furthest end away from the body,’ says Stanford University doctor Patrick Burns who works on the RTP series medical team. ‘So that when you run it creates that kind of constant pressure to squeeze out whatever juices is in it.’ They use gauze to absorb fluid and cover that with thin micropore tape, before applying adhesive spray. For blisters on the toes, a ‘special kind of origami taping job’ may be needed. Elsewhere on the foot they install highly-woven tape called Elastikon on top of the paper tape.

Compeed does not feature. ‘They're kind of expensive,’ says Burns, 'when we’re dealing with that many feet.' By contrast, a study conducted during RacingThePlanet events found that 3M micropore paper tape reduced blisters by 40 per cent.

Following the science?

The current state of the blister business is complicated. Compeed is ubiquitous but expensive, and disregarded in ultrarunning. Traditional treatments can be alarming and ineffective. Rebecca Rushton, for instance, warns against heating a pin in a cigarette lighter flame to ‘sterilise’ it before piercing a blister. ‘You’re just leaving carbon in there,’ she says. ‘And then carbon will become an irritant.’ (If you must take a fiery approach, blue flame is preferable.) Duct tape, long-favoured, is also problematic. ‘It doesn’t stretch,’ says Tod Schimelpfenig of the National Outdoor Leadership School in the US. ‘The adhesive can really irritate people. And if you buy the inexpensive duct tape, it’s not very slick.’

Choice of footwear is indisputably important. Tom Scales, a technician at Profeet in London, explains that, paradoxically, modern running shoes are less biddable to personalisation than traditional leather walking boots. Leather ‘wears-in;’ synthetic material will not.

With running shoes, Scales advises understanding the variance of the last used to construct the shoe. The traditional width fitting for men’s shoes is a D-width. Within this category, Adidas and Hoka tend narrow. Asics used to be narrow but ‘they’re starting to widen up’. Saucony are broad and brands that offer a wider fitting – 2E and 4E – include Brooks, Asics and New Balance.

Lacing can compensate for pressure points. A ‘heel lock’ – using the secondary top eyelets – sits the ankle more firmly to reduce rubbing on the Achilles area, according to Scales. Leaving the bottom eyelets unused creates a more relaxed medial fit in a shoe that is blistering across a big toe. A ‘window technique’ – missing out several central rungs of lacing, reduces pressure on the medial and internal cuneiform bones on top of the foot. ‘It gives you a little more accommodation over that,’ says Scales. (See

Release the pressure

With lubricants, the way powder or grease can reduce friction was identified by Naylor in the 1950s. However, a later study in 1981 found that while mineral oil, petroleum jelly and glycerin all initially reduced the co-efficient of friction, after one hour of rubbing the CoF had returned to baseline and after three hours it was in fact about 35 per cent above. (The researchers hypothesised that as the test substances were absorbed into the skin there was a slow and prolonged hydrating effect, that in turn increased friction and decreased the lubricating effect).

The change in recent years is the advent of new substances – dimethicone for liquids and Polytetrafluoroethylene, better known as PTFE or Teflon for solids. Compared to talc or petroleum jelly, these appear to lower friction for longer. US brand 2Toms, co-founded by runner with a PhD in surface chemistry, produces a liquid roll-on called SportsShield, which contains dimethicone and aloe vera extract. Their ‘BlisterShield’ foot powder combines PTFE with wax.

Two other new products seem closest to bridging the gap between the scientific understanding of the role of friction and practical blister prevention. The first is Armaskin. Liner socks are nothing new. They operate on the principal that if you create an intermediary boundary with a lower friction than the skin-sock join, then shear will take place there, not within the skin. However, while most liners are similar to standard socks, Armaskin combines a grippy silicone lining with a slippery outer surface. ‘The lower friction level is 100 per cent going to be between the two sock layers,’ claims Ian Bridger, the firm’s marketing manager. An independent study found a ratio of 3.3 to 1 in the coefficient of friction between the internal and external surfaces of the ArmaSkin sock. That compared with a 0.98:1 ratio with the study’s point of comparison, a Dunlop ‘Performance Sports Sock’ made of a cotton, polyester, nylon, elastane blend. ArmaSkin is also quicker to use than the construction of a bespoke preventative taping job, and is more resistant to water.

However, the issue with all-over foot solutions – lubricants or liner socks – is that they are not targeted. They reduce friction all over foot, but in some sites, friction is key. Without it the shoe will not stay in place, and traction can be reduced.

The search for a ‘targeted’ solution inspired Marty Carlson, who spent 16 years as Director of Habilitation Technologies at a Minnesota hospital, to develop a self-adhesive film that combines slippery PTFE with adhesive backing like a Compeed. The resulting ‘ENGO’ patch comes in shapes designed to fit the heel and other areas such as under the instep.

Crucially, unlike Compeed, you do not apply an ‘ENGO patch’ to the skin. Instead, it goes directly on the shoe, creating a more durable alternative than materials affixed to sweaty feet. ENGO, Carlson says, ‘allows the skin in that at-risk location to “glide” a small amount back and forth, experiencing less friction-induced shear’.

The coefficent of friction (CoF) of materials typically used in shoe insoles, uppers, and the material at the back of the heel is typically between 0.5 to 0.8, ENGO patches, by contrast, have a top surface-to-sock interface CoF of 0.2. Carlson claims that they can reduce the maximum possible surface friction/traction on foot skin by approximately 60 to 75 per cent in blister-prone locations.

Unlike with other approaches, moisture also makes little difference. With virtually all insole surface materials, moisture in the 0-30 per cent range by weight will increase the CoF. However, the CoF between a sock and an ENGO patch is consistently close to 0.2 or less.

That’s great news for us runners, who know all too well how what some dismiss as a minor irritation can be a purveyor of suffering and dasher of dreams. Something that the inventor of still the world’s leading treatment also understands: ‘The reality here is that this small annoying problem, which people didn’t really want to talk about, was more annoying than people really want to confess,’ says Backsell. ‘It is sufficiently severe to prevent you from doing what you want to do.’ Now though, with the latest products finally following the science to deal more effectively with the underlying issue, it seems that some 5,000 years after Ötzi filled his shoes with moss we may finally be on the verge of winning our war with our old enemy.

Man vs Blisters

4 million BC: Our primate ancestor first stands on two legs.

One hour later: First blister appears on sole of said primate's foot.

3,400BC: Prehistoric anti-blister footwear uses a mesh of braided linden bark and moss lining.

100 AD: Roman soldiers’ caligae sandals feature straps designed to avoid rubbing certain parts of the feet.

1951: Blister research at the British Army’s Experimental Research station at Byfleet reveals the role of friction in blister formation.

1972: Marion B. Sulzberger identifies shear forces within the layers of the skin, not friction on the surface as causing blisters.

1984: First Compeed anti-blister plasters hit the market.

Today: Armaskin socks and Engo skin patches my finally give us victory over our old enemy.

You Might Also Like

Yahoo Finance

Yahoo Finance