What are electrolysers? How is hydrogen produced and how do fuel cells use the energy?

Electrolysers and fuel cell systems are the key equipment for the production and use of hydrogen.

More than 95 per cent of hydrogen is currently made using fossil fuels, mainly coal and natural gas, because of their low costs. However, governments' climate policies and incentives will make the production of green hydrogen, which uses renewable energy, economically viable, presenting big business opportunities.

Here is what you need to know about electrolysers and fuel cell systems.

Do you have questions about the biggest topics and trends from around the world? Get the answers with SCMP Knowledge, our new platform of curated content with explainers, FAQs, analyses and infographics brought to you by our award-winning team.

Electrolysers use electricity to split water into its constituents - hydrogen and oxygen - via electrolysis, which involves chemical reactions and the interchange of electrically charged atoms and ions. The hydrogen produced is considered "green", or low carbon, if renewable or nuclear power is the energy source.

When the hydrogen is consumed, the process is reversed. In vehicles, the hydrogen is recombined with oxygen to produce electricity, heat and water through a fuel-cell system.

A typical electrolyser uses 9kg of water to make 1kg of hydrogen, with the remaining 8kg released as oxygen. In a standard fuel cell, for every kilogram of hydrogen consumed, 9kg of water is released. A sustainable source of water is a key determinant for siting green hydrogen production projects. Availability of abundant cheap renewable energy is another.

In power plants, a small percentage of green hydrogen can be blended with natural gas without equipment modification to reduce the plants' carbon intensity. A hydrogen blending ratio in excess of 50 per cent requires equipment retrofitting, according to Finnish energy and marine tech firm Wartsila.

Power generation accounted for 63 per cent of Hong Kong's greenhouse gas emissions in 2022, according to the Environment and Ecology Bureau. Globally, fossil fuel-based power generation contributed 40 per cent of total energy-related carbon emissions in 2021, according to data from the International Energy Agency.

In steel plants, hydrogen can be used as an oxidising agent to produce low-carbon steel. Pilot projects are being built in many countries.

In transport, hydrogen fuel cell vehicles have been in use for more than two decades, with some 14,500 units sold worldwide last year, according to SNE Research. Recently, some ships have started using fuel blended with hydrogen derivatives like methanol and ammonia to lower emissions.

Ultimately, the climate mitigation benefits generated by the adoption of green hydrogen will depend on the pace of cost reduction and production and supply chain development. These will depend on government policies and technology advancement.

China's green hydrogen supply is forecast to rocket from around 350,000 tonnes last year to 6.8 million tonnes in 2035 and 71 million tonnes in 2050, according to Shanghai-based research and consultancy Integral.

The first electrolysers and fuel cells were invented in the 19th century. Commercial application of electrolysis was rare since hydrogen has for decades been made cheaply with fossil fuels, through the reaction of natural gas or coal with steam, a highly carbon-intensive process.

Industrial use of fuel cells came many decades later to generate electricity for off-grid applications, such as space expeditions and satellites. These were followed by power backups for buildings and in remote areas, and transport.

Commercial production of green hydrogen only started around five years ago as a key decarbonisation and clean energy storage solution for the future, according to Assaf Sayada, CEO of Israel-based Hydro X, which is seeking to commercialise its know-how to safely transport the low carbon fuel.

"The world understands there is absolutely no way to reach the decarbonisation objective of the planet without a major role played by green hydrogen," he said.

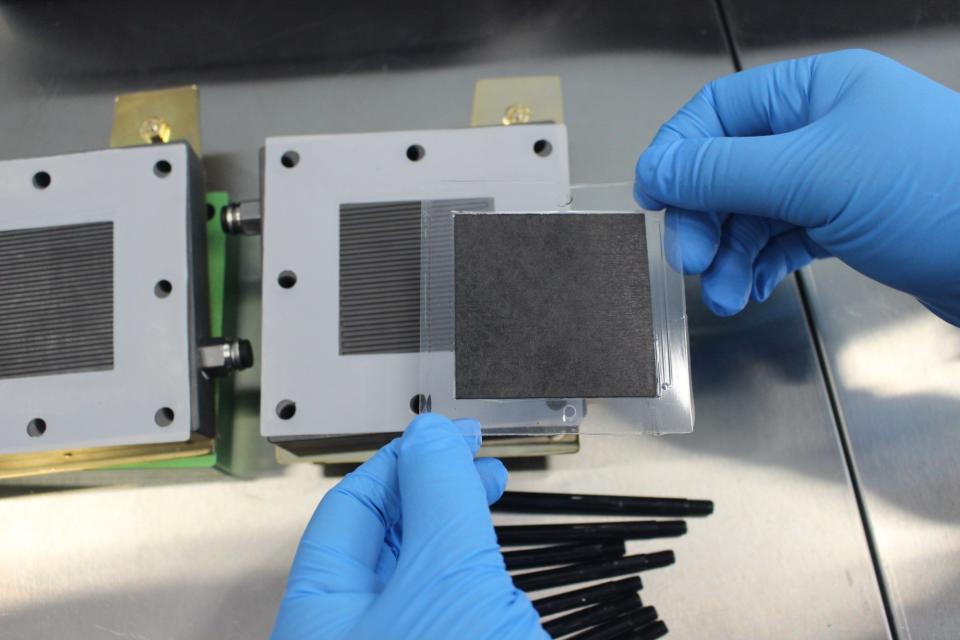

Hong Kong start-up Epago has developed a new type of membrane, a core component in hydrogen fuel cell batteries, bringing down production costs and manufacturing time. Photo: Yujie Xue alt=Hong Kong start-up Epago has developed a new type of membrane, a core component in hydrogen fuel cell batteries, bringing down production costs and manufacturing time. Photo: Yujie Xue>

What are the main electrolysis technologies available on the market?

Alkaline and proton exchange membrane (PEM) are the two main commercially available technologies.

Solid oxide electrolysis (SOEC) is close to commercialisation, while anion exchange membrane (AEM) is still in the early stages of development.

Alkaline electrolysers were first used over 100 years ago for producing ammonia - a key fertiliser ingredient - using hydropower. Hydrogen is first produced from natural gas, before it is mixed with nitrogen to produce ammonia, under extreme heat, pressure and in the presence of a catalyst.

PEM electrolysers were developed in the 1960s by General Electric for space applications to generate oxygen for astronaut life support. Subsequently, they were used to make hydrogen commercially for industrial applications, such as petroleum refining, glass and metals production.

A precious metal like platinum or iridium has to be used as a catalyst in PEM electrolysers, while nickel can be used in alkaline ones.

However, PEM electrolysers can operate effectively at high current densities - the amount of electric current travelling per unit cross-section area - and can adapt to rapid changes in power levels. This makes them more suitable for deployment with renewable energy, whose supply can be intermittent and varies with the weather.

"China has made great strides in lowering the cost and improving the performance of alkaline electrolysers," said Gao Xiaoping, chairman and general manager of CM Xiageng Hydrogen Energy Technology, a green hydrogen equipment maker backed by the Fujian government and state-backed conglomerate China Merchants Group. "Still, we need more technology advancement to better cope with volatile output of wind and solar energy production."

Alkaline electrolysers are more likely to dominate China's green hydrogen market than PEM electrolysers, which are more common in Europe and the US, according to Amily Guo, China refining and chemicals analyst at UBS.

This is because the cost of alkaline electrolysers in China has fallen to a third that of the PEM type, making them more attractive for large green hydrogen projects being built in the nation's renewable energy-rich northern regions.

However, Guo expects the price difference between the two types to narrow after 2030 as the technology continues to advance, allowing PEM products to gain market share in China.

Currently, the cost of coal-derived "grey" hydrogen is about 10 yuan (US$4.10) per kg, she noted. There is still a substantial gap compared with 30 yuan per kg of green hydrogen made by alkaline electrolysers and 25 yuan per kg produced by PEM ones, which means financial incentives are needed for adoption of the green option.

This article originally appeared in the South China Morning Post (SCMP), the most authoritative voice reporting on China and Asia for more than a century. For more SCMP stories, please explore the SCMP app or visit the SCMP's Facebook and Twitter pages. Copyright © 2024 South China Morning Post Publishers Ltd. All rights reserved.

Copyright (c) 2024. South China Morning Post Publishers Ltd. All rights reserved.

Yahoo Finance

Yahoo Finance